Retrofitting a rubber torsion axle onto older vehicles that originally had a different type of suspension is a question that brings into focus both the technical feasibility and the advantages of modern suspension systems. Rubber torsion axles have become a popular choice in vehicle suspension due to their superior performance, durability, and efficiency. Understanding how and why they can be retrofitted into older vehicles requires an exploration of both their engineering principles and the practical benefits they offer.

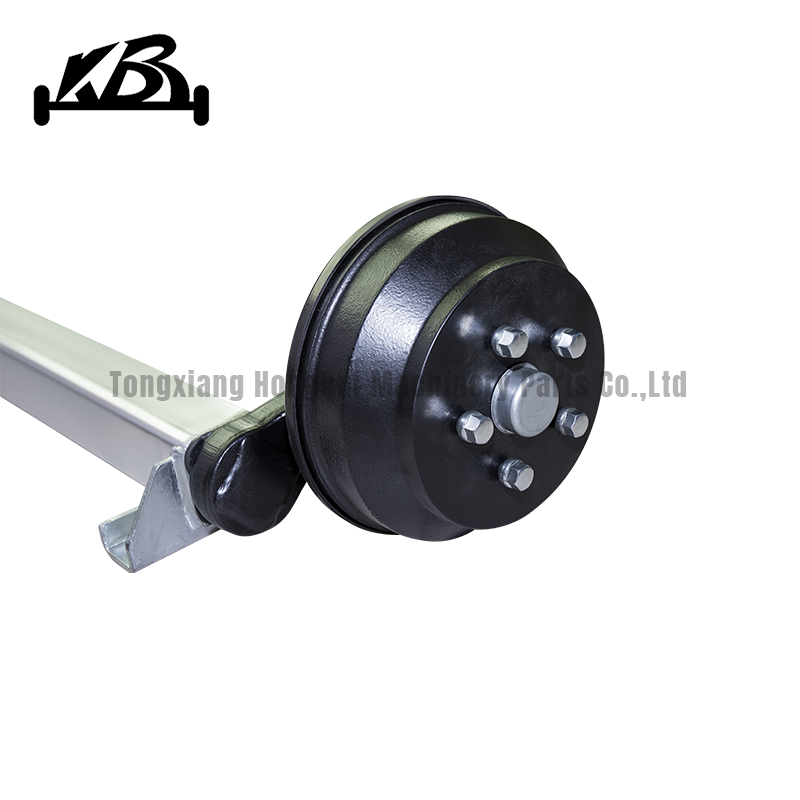

A rubber torsion axle functions through the use of a metal core encased in rubber, which twists as the vehicle moves. This design allows the axle to serve both suspension and damping functions, providing a smoother and more stable ride compared to traditional leaf spring systems. The inherent properties of rubber allow it to absorb shocks and vibrations effectively, resulting in increased comfort for the vehicle's occupants and better handling, especially on rough or uneven roads. The lightweight nature of rubber torsion axles also contributes to improved fuel efficiency, as less energy is required to move the vehicle.

When considering the retrofit of a rubber torsion axle onto an older vehicle, several factors need to be taken into account. Firstly, the compatibility of the axle with the vehicle's existing structure is crucial. Older vehicles designed for leaf springs or other types of suspension may require significant modifications to accommodate the new system. This could include alterations to the mounting points, adjustments to the vehicle's frame, and ensuring that the new axle aligns correctly with the vehicle's wheels and braking system. However, many retrofit kits are available on the market, designed to facilitate this process by providing the necessary components and instructions to adapt the vehicle's structure.

The advantages of retrofitting a rubber torsion axle are substantial. For one, the improved damping and shock absorption lead to a noticeably smoother ride. This is particularly beneficial for older vehicles that may have a more rigid and uncomfortable suspension setup. Additionally, the durability and low maintenance requirements of rubber torsion axles mean that once installed, they will likely need less attention and repair compared to traditional suspension systems. This can be a significant advantage for vehicle owners looking to reduce long-term maintenance costs and improve the reliability of their older vehicles.

Moreover, the enhanced handling characteristics provided by rubber torsion axles can significantly improve the driving experience. Older vehicles retrofitted with these axles can benefit from better stability and control, especially when navigating corners or encountering bumps in the road. This not only enhances safety but also increases the overall driving pleasure. Furthermore, the reduction in weight due to the lighter construction of rubber torsion axles can contribute to better fuel efficiency, a critical consideration for older vehicles that may not have been designed with modern fuel-saving technologies in mind.

中文简体

中文简体